EV wiring harnesses

Share

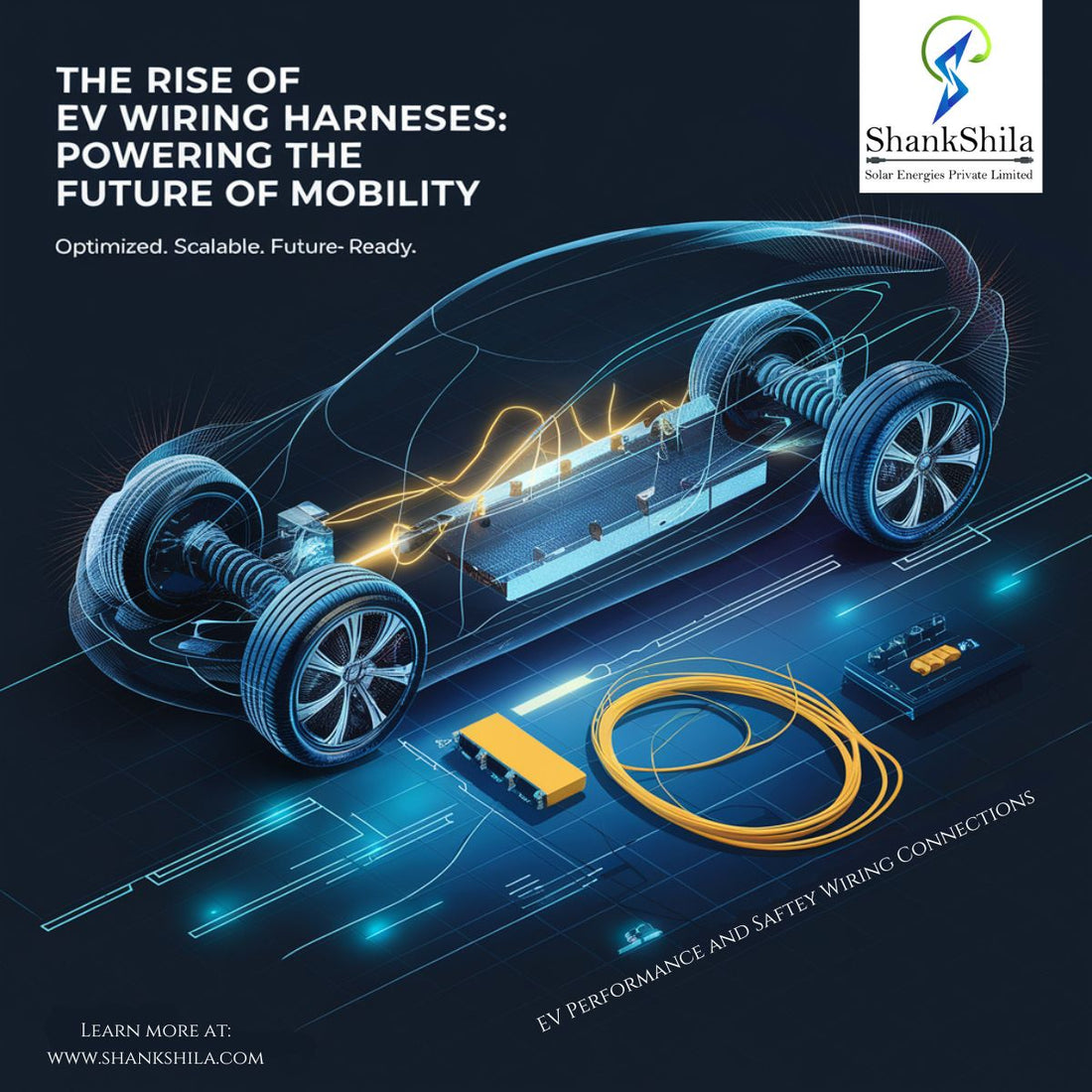

As the EV revolution gains momentum, one crucial yet often overlooked component is the EV wiring harness—the nervous system of electric vehicles. It’s not just about connecting components; it’s about ensuring performance, efficiency, and safety in high-voltage environments.

But here’s the challenge: Mass production, cost efficiency, and scalability.

The Role of Wiring in EV Performance & Safety

Unlike traditional vehicles, EVs demand high-voltage cables that must withstand extreme conditions while ensuring minimal power loss. A poorly designed wiring harness can lead to:

✅ Voltage drops reducing battery efficiency.

✅ Overheating risks leading to safety concerns.

✅ Complex installation & maintenance, increasing manufacturing costs.

The Challenge: Scaling Up Production Without Compromising Quality

For manufacturers, mass production is no easy feat. The biggest roadblocks?

🔸 Weight & Space Optimization – EVs need lightweight yet robust harnesses.

🔸 Automation in Manufacturing – Manual processes slow down scalability.

🔸 Cost vs. Performance Trade-offs – Using high-quality materials while keeping costs competitive.

Future Trends in EV Component Manufacturing

With the EV industry evolving, manufacturers must stay ahead by:

🚀 Adopting lightweight, high-efficiency materials to reduce energy consumption.

🚀 Implementing smart & modular wiring solutions for faster assembly.

🚀 Investing in AI-driven quality checks to enhance reliability.

At Shankshila Solar Energies, we understand the pain points of EV manufacturers and provide high-quality, scalable, and cost-effective EV wiring harnesses that meet global standards. Let’s power the future of mobility together!